Garum was made only with small gutted fish like sardines and mackerels, brine, and time to ferment (since the process could take almost one year!), where microorganisms and enzymes present in the fish’s guts were crucial to the chemical process from where its robust flavors come from, breaking down the flesh and turning it into a thick liquid.

The recipes changed over the centuries and the regions (with the adoption of various aromatic herbs, spices, or even wine) as well as its preparation method, of course.

Our modern adaptation

For almost two decades, we’ve been studying and employing the process of making garum — using ingredients from our land to extract the most profound, exciting flavors from plant- and animal-based ingredients (from chicken wings to mushrooms, and all kinds of vegetables).

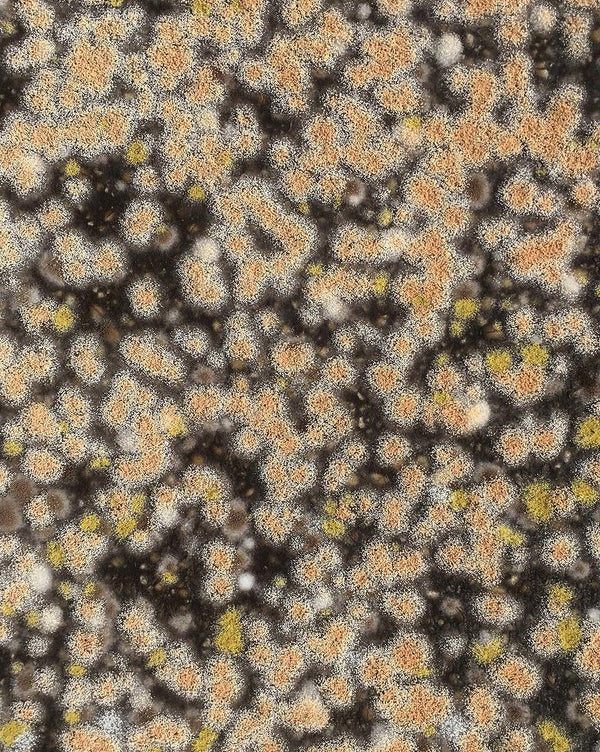

Where traditional recipes rely on the naturally occurring enzymes in fish intestines to break down the fish into a sauce, we use koji to recreate a similar process. By using koji, we can then experiment with a wider range of high-protein ingredients found in nature, using the same process but with different ingredients to extract umami-rich flavors from them, yet less tangy and less salty.

We realized that there was an opportunity also to expand the role of garum to other kingdoms, such as vegetables or even fungi, to produce powerful flavors as well. Koji also proved to be very advantageous (and faster) to create sauces that were both unique in flavor and still delicate.

The process begins with pressing the raw ingredient, mixing that in salt and water, fermenting from 6 to 10 weeks (depending on the ingredient), then straining for the final product: a powerful, savory liquid seasoning.